Company

A little bit of Green Economy

Towards a cleaner future, energy-saving investments

Producing energy from renewable sources will be the future, but saving energy by making consumption more efficient is feasible now, even cutting oils from renewable sources.

Since 2012, all our machines using whole grain oil have been equipped with oil based on vegetable esters, a thank you to these green oils, also to the operators.

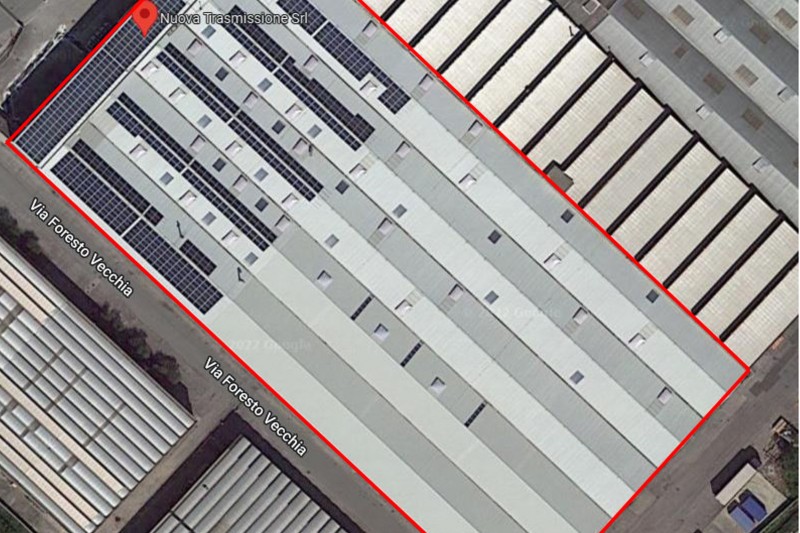

Already in 2014, we replaced all the neon tubes in the company with LED equivalents, for the study of which it took a couple of months, type of LED, color rendering and radiation emission, light output in lumens / watts, we bought a product in China with a light output of over 125 Lm / W, then not present on the Italian market except at crazy prices. The investment paid for itself in about 3 years, a saving of about 17 kW/h, about 500 lamps. Secondly, we replaced all the methane hot air generators with Robur methane heat pump units, with an efficiency of up to 164%, in practice we halved the consumption of methane. By bringing the new Robur boilers outdoors, we eliminated 3 generators, 2 boilers and a refrigeration unit for air conditioning, which also provide cold water in the summer to condition the offices and, if desired, the production departments. As a third step, we installed a 70 kW photovoltaic system on the roof.

In 2017 we re-did all the roof coverings, about 8,000 m2, and installed another 174 kW of photovoltaic panels.

In 2022 we will install a further 201 kW of photovoltaics on the roof of a new building we have purchased, adjacent to the one we are using, for a total of 445 kW nominal, on which we built the new CNC lathe department last year, the contract predates the crazy increases in energy prices, which means that in about 3 years we will pay for everything using all the electricity produced.

Voci Correlate

Scopri e leggi le altre voci