Company

Future aims

Developments and investments plans

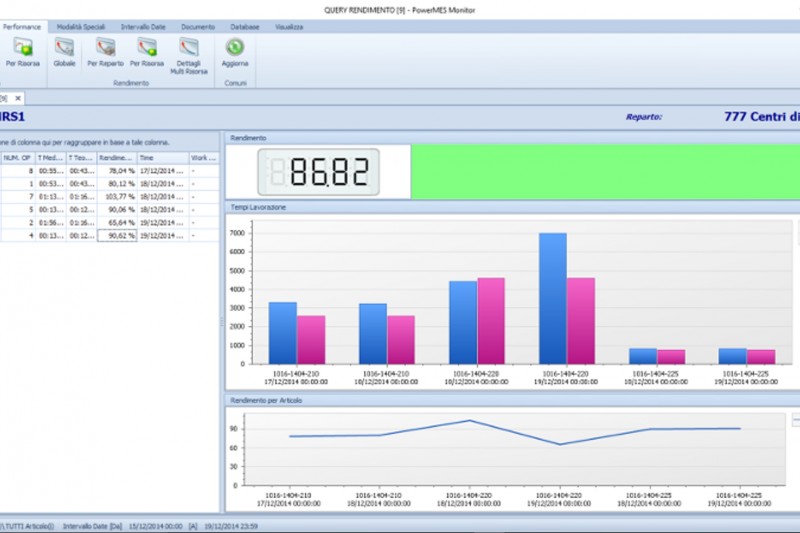

We have long been an Industry 4.0, but digitisation never stops, it is constantly evolving, from the machines to the software that manages almost everything. Millions of digital data that in real time build up our knowledge base, drawings, process data, measurements and certifications, time recording, archiving aimed at product batches, both for us and for our customers. Almost all the process and measuring machines are on a WiFi network, exchanging data, archiving, control, continuous monitoring, for cost checks and complex analyses. It is possible to connect the machine manufacturers remotely via the internet for remote assistance and remote diagnostics. Striving for zero waste, aiming for the highest quality in our sector, giving the customer more than he expects is our mission.

In addition to the machine tools, we have extended our digitalisation, with 3 new Kardex rotating drawer warehouses connected to the network. Tool and equipment retrieval is done automatically; when the production sheet is entered, the system integrated into the management system sees the code of the material in production and in sequence presents the drawers containing the tools and equipment necessary for the execution of the parts. This leads to the certainty of always using the same tools, the same creators (serial number), the same gripping systems, in a univocal way to avoid searching in the various drawers what is needed and also possible errors, the operator is guided to the choice made at the first execution of each code.

Voci Correlate

Scopri e leggi le altre voci