Products

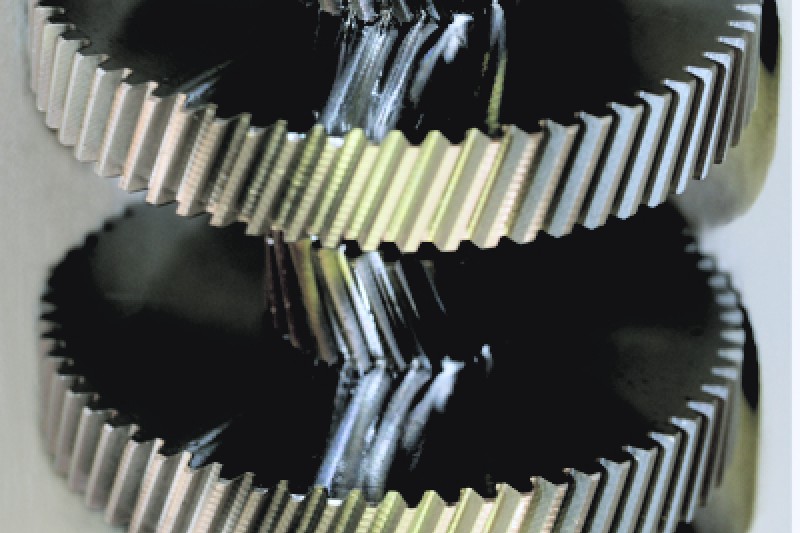

Gears

Grinded gears

Gears made out of grinding or skiving process

Modern CNC grinding machines with automatic loading systems, we are the right partner for those who want high precision and low costs, we have all

High precision gears

Since 2002, we manufacture gears with the most modern NC hobbing machines and the highest quality cutting hobs. We can supply gears in quality Din

Forced joint gears

These combined gears represent the right solution to avoid the welding procedure guaranteeing a better torsional resistance as well as low

Splined synchronized gears

We can synchronize two or more hobbings among them or with other toothing previously made as, for instance keyways, threaded bores, etc.

Extra-thin gears

Improved technologies ensure errors <= 0.03 mm between bore and gearing and minimal eccentricity errors

Micro-gears

Micro gears from module 0.3, in the most varied materials, possibility of gear grinding from module 0.5, from diameter 6 mm. Micropulleys in pitches